Process Safety Blog

Sodium Hypochlorite vs Chlorine for Water Treatment Facilities

Sodium Hypochlorite vs Chlorine for Water Treatment Facilities

Water processing facilities have a requirement to ensure the quality of the output meets consumption or discharge requirements via an appropriate treatment or disinfection process. Depending on the operational and demand requirements, the risk profile and regulatory requirements, facilities can use liquid or gaseous chlorine, hypochlorite (import or onsite generation) or UV treatment. This blog discusses the overall pros and cons of chlorine vs sodium hypochlorite with a case study of how an Australian water utility decided to move to hypochlorite from liquid chlorine.

Chlorine is used in wastewater treatment plants to kill harmful bacteria and pathogens that may be present. Chlorine disinfection is a reliable and cost-effective way to ensure that the water leaving the treatment plant is safe to be released into the environment. Additionally, chlorine helps to remove unpleasant odours and tastes from the water, making it more palatable for reuse or discharge. Historically, some facilities have chosen liquid chlorine as their disinfectant of choice however many are moving to alternative treatment methods because of safety concerns.

Chlorine is toxic, corrosive, reactive and has adverse environmental effects if the release is uncontrolled. If there is an uncontrolled release of liquid chlorine, these effects can be magnified and prolonged.

Sodium hypochlorite and chlorine are both commonly used as disinfectants. The choice between the two depends on the specific treatment requirements, required capacity and facility conditions.

|

|

|

| Find out about our upcoming HAZOP LEADER Training Course HERE! | For those more experienced, we offer an ADVANCED HAZOP Training Course HERE! | Find out about our online INTRODUCTION TO PROCESS SAFETY E-LEARNING Course HERE! |

Benefits of sodium hypochlorite:

Easy to handle: Sodium hypochlorite is a clear, highly stable solution that is easy to store and transport, making it less hazardous than liquid chlorine.

Low toxicity: Sodium hypochlorite has negligible acute toxicity compared to chlorine, reducing the risk of harm to workers handling the chemical.

Benefits of liquid chlorine:

- More effective: Chlorine has a stronger disinfectant effect compared to sodium hypochlorite, making it a more effective and practical choice for some water treatment applications and specifically larger facilities.

- Lower cost: Chlorine is typically less expensive than sodium hypochlorite, making it a cost-effective choice for facilities with large treatment needs.

- Longer shelf life: Chlorine has a longer shelf life compared to sodium hypochlorite, making it a more practical choice for facilities with limited storage space.

Key safety features of a water treatment facility using chlorine for disinfection include:

- Chlorine storage and delivery system: A secure and appropriate storage area for chlorine drums and a reliable delivery system for introducing chlorine into the water.

- Monitoring and control systems: Monitoring and control systems are necessary to measure chlorine levels in the water and adjust the dose to maintain optimal disinfection levels.

- Ventilation systems: Adequate ventilation systems are necessary to prevent the build-up of chlorine gas in the disinfection buildings and outside

- Safety systems: Chlorine detection and Emergency shutoff valves and alarms to alert personnel in case of spills or leaks, as well as eye wash stations and safety showers, are necessary to ensure the safety of personnel in the event of an emergency.

- Pipes and pumps: Chlorine-resistant materials should be used for pipes and pumps to prevent corrosion and ensure the longevity of the system.

- Storage and transportation: Chlorine should be stored and transported in appropriate containers designed to withstand its corrosiveness and reactivity. Reduction in inventory should be balanced with the frequency of changeover

- Handling: When handling chlorine, appropriate personal protective equipment (PPE), e.g., breathing apparatus, is needed.

- Emergency planning: Industrial facilities should have emergency plans to respond to spills or releases of chlorine, including evacuation procedures and emergency response teams.

- Training: Personnel involved in the handling, storage, and use of chlorine should be properly trained on the hazards of chlorine and how to handle it safely.

Replacing a chlorine dosing system with sodium hypochlorite is an excellent Hierarchy of Controls approach (Substitution) to reduce the overall process safety risk, however, there are still risks associated with both its storage and/or on-site generation which need to be properly assessed during your management of change process. Since sodium hypochlorite is a strong oxidising agent, something of specific concern is the rapid generation of chlorine gas if acid is inadvertently mixed with sodium hypochlorite, as occurred in this incident (https://www.csb.gov/).

Case Study

I have previously written about the importance of process safety management (PSM) and a robust Safety Assessment approach for water treatment plants. One of the recent safety wins for a Water Utility servicing a major city in Australia was the decision to permanently decommission its chlorine system in favour of sodium hypochlorite.

History:

Following a number of minor chlorine loss of containment incidents and near misses on the site, the system was shut down and temporarily decommissioned to address the root causes of these incidents. For this period, while material and equipment repair and replacement were being completed, the site temporarily stored and used sodium hypochlorite to ensure continuous operation of the plant. This also prompted the need for a robust Process Safety audit of the organisation, which ultimately led to kicking off the Process Safety Management improvement program.

Safety Assessment:

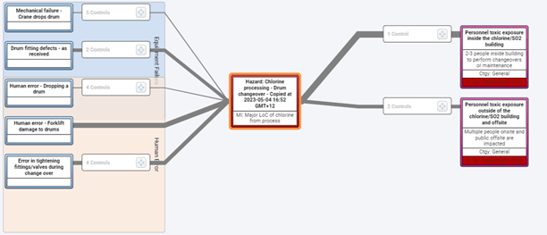

As part of this PSM program, the safety assessment process identified the causes and assessed the risks of both a minor and major loss of containment of chlorine that could occur on the installed system, from both process equipment/piping and from drum handling. A hierarchy control suggested during the So Far As Is Reasonably Practicable (SFAIRP) workshop was to determine whether the chlorine system could be permanently decommissioned in favour of making the sodium hypochlorite system permanent.

Challenges:

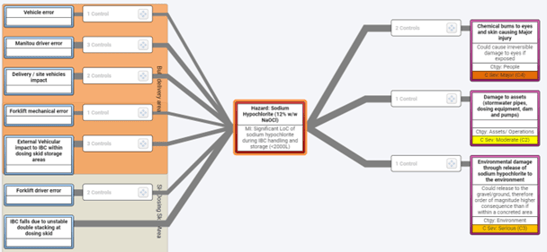

The current temporary sodium hypochlorite system was commissioned hastily to prevent plant downtime while the chlorine system issues were being addressed. This meant there were still hazards and risks associated with this sodium hypo system, which needed to be assessed.

At the time of doing this assessment, the operations and maintenance teams had already invested both resources and money under pressure in repairing and replacing equipment/piping within the chlorine system. They were therefore also keen to recommission the system.

Outcomes:

The results from the assessment showed that while the likelihoods of a Loss of Containment were similar for both systems, the overall consequences and hence risks of the sodium hypochlorite system were much lower across each equivalent scenario assessed.

The above process and outcome were documented to demonstrate to the management and operations teams the direct risk comparison between the two systems. The recommendation to switch permanently to sodium hypochlorite was ultimately accepted, which demonstrated the site’s adherence to the Model Work Health and Safety Act through a hierarchy of control approach.

Ready to take your process safety strategy to the next level?

Explore our CONSEQUENCE MODELLING SERVICE, to build practical, defensible safety solutions. Strengthen your understanding of compliance and ignition risk control with our HAC TRAINING course.

Have questions or need guidance? GET IN TOUCH. We're here to help.