Process Safety Blog

A Process Safety Approach to Bulk Liquid Transfer at Ports

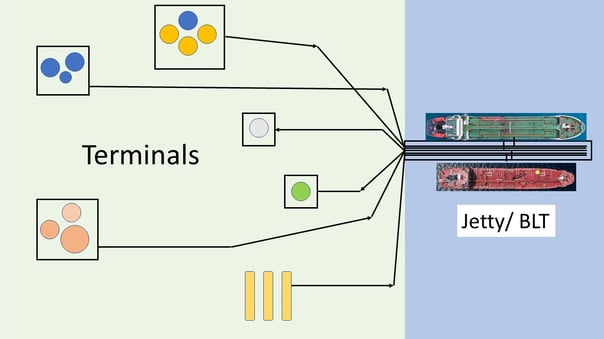

Bulk Liquid Terminals (BLTs) located at shipping Ports have the primary function of facilitating the transfer of fuels, chemicals, feedstocks and consumer products between nearby storage facilities and ships.

Transfer parcels either:

a) originate in the storage facilities and are exported to ships via shipping terminal OR

b) are imported from a ship into the land-based storage facility.

It is not unusual for a BLT to have overall coordination responsibility for the transfer of products such as:

- Gasoline & Diesel

- Liquified Gases (LPG/ LNG)

- Bitumen

- Chemicals for use in manufacturing or food production

- Agricultural products

BLTs can expect to see a wide variety of ship types including chemical carriers and liquified gas carriers with differing flag status’ to ownership models (charter, spot, owned etc). These often berth at Finger or Dolphin Jetties or berths at Quays. Some are dedicated to specific users, and some are multi-use.![]()

Hazard and Risk Profile of the Transfer Process

The risks associated with ship transfers can be split into 4 areas:

|

# |

Location |

Key Risks |

|

1 |

Filling or discharging from a storage facility at or near Port |

Overfilling of tanks/ vessels |

|

2 |

Transfer to berth via wharf lines |

Potential for loss of containment from pipelines on port facilities caused by human error, surge movements and asset integrity issues |

|

3 |

Wharf Line on Berth |

Similar to above, however control of the area is likely more stringent |

|

4 |

Hose/ MLA Connection to Ship |

Similar to above |

|

5 |

Ship Manifold |

Overfill, asset integrity issues, Human error potential etc |

The risks associated with land-based storage facilities are generally well understood however, ship loading/ unloading operations often lack a systematic approach to risk management. This requires the coordination of several duty holders (storage, terminals, product owner, shipping etc), some of which are not mature in risk management which is often a barrier to the process.

General Risk Management Challenges in Port Operations

Ports are busy and complex operations with a diverse number of activities occurring on them including container movements, logging, bulk liquids transfer and storage of materials. The following safety management challenges exist within port operations:

- Numerous duty holders – asset owners, personnel, shipping, product owners

- Multiple security zones with differing levels of access are allowed.

- Complex traffic movements

- Differing levels of automation and a significant need to rely on personnel competence

A Recommended Approach for Assessing the Risks for Bulk Liquids Terminals

The following safety assessment model is a popular approach for regulated MHF-styled production facilities and can be used to assess operations on BLT terminals.

To successfully implement this process, the following is required:

To successfully implement this process, the following is required:

- Clarity on what laws and regulations apply both on landside operations and marine operations.

- Drawings for typical ships coming into the terminal – this is a requirement to do an effective hazard and risk assessment for the loading/ unloading operation

- Getting the right expertise in the room – this includes marine, terminal and wharf operations staff.

Case Study – A Practical Implementation of this Approach

Port Taranaki (PTL) located on the west coast of New Zealand, services the local energy, dairy, agricultural and logging industries. In 2019, Safety Solutions was engaged to help review the need for an upgraded firewater system for their Newton King Tanker Terminal (NKTT) which services the energy industry. During this activity, the need for a Process Safety Management (PSM)/ Major Hazard Facility (MHF) styled approach on NKTT was identified as being required to manage the level of risk.

NKTT is a finger jetty arrangement with 2 berths on opposite sides of the wharf.

The operations present on NKTT include:

- Export of hydrocarbon condensate

- Export of LPG

- Export of Methanol

- Import of Gasoline and Diesel

- Import of Bitumen

- Import of Caustic Soda and Nitric Acid

The storage terminals are either located on Port Taranaki’s land or within a few kilometres of NKTT. The 8 users of NKTT own and operate their pipelines, Marine Loading Arms/ Hoses and equipment on NKTT with Port Taranaki personnel controlling/overseeing the overall operation on the wharf.

The risk profile of NKTT is influenced by:

- A mix of flammable and toxic products from different users

- Co-incident loading/ unloading

- Varying ship sizes and types

- Weather and tidal constraints specific to this coastline

|

|

|

|

| Purchase our INTRODUCTION TO BOWTIES E-Learning Course | Find out about our upcoming HAZOP LEADER Training Course | Find out more about our HAZARD ID FACILITATION Consulting Services |

Challenges in the process

- The accommodation of several process safety cultures with differing levels of maturity

- Developing clarity on where responsibility starts and stops for loading/ unloading operations.

- Developing an understanding of how escalated events should be assessed (e.g. when 2 ships are at the same wharf)

- Ensuring that marine expertise was available.

This type of operation is somewhat unique in comparison to dedicated terminals (e.g. for a specific user or product). Because of this, PTL leadership decided to take a port industry-leading approach to risk management.

The Safety Assessment was run in 4 phases:

Phase 1: Hazard Identification Workshops – with the goal of identifying how major incidents could occur. This step was split into 2 steps including:

- A HAZOP of the interface of shore-to-ship

- A HAZID of the loading/ unloading operation with a specific focus on port and simultaneous operations.

Phase 1 was run separately with each user of NKTT. 30 major incident scenarios were identified focusing around 5 locations.

Phase 2: Risk Assessment Workshops – to assess the current risk and identify critical controls. Risk Assessment Bowties were developed, and the controls were evaluated for their effectiveness to determine the outcome risk. During this process, threats and controls were assigned to different users based on ownership & influence over the performance of the control.

The bowtie risk assessments identified some scenarios & locations that had high risk and needed additional controls however many scenarios had sufficient controls to manage the risk.

Phase 3: SFAIRP Assessment Workshops– this step challenged the users and PTL in the area of good practice, application of standards and positive consideration of additional controls. New controls were identified in this step for consideration

Phase 3a: Escalation Workshop – this step examined the validity of the risk assessments when 2 ships were being loaded at the same time.

Phase 4: Implementation - The actions and findings from Phases 1 and 3 are in the process of being investigated, implemented and closed out including:

- Updates to PTLs emergency response plans

- The implementation of a control assurance program where PTL perform assurance on all controls to ensure critical controls are operational and have the needed level of performance.

Benefits of the Process

Whilst time will tell on the impact of this program of work, the following benefits were identified:

- Enhanced communication between the users and PTL with a specific focus on process safety and asset integrity.

- Clarity on what controls are important to manage the risk of an event on the wharf or ship

- Immediate actions are taken on some higher-risk scenarios (e.g. increased firewater at specific locations).

- An overall improved understanding across several duty holders on how high consequences can occur, how they can be prevented and who owns these controls.

The success of this type of process required vision and commitment by Port Taranaki to embark on a process not normally performed in Port operations. Their leadership saw it as a necessary process to ensure they were performing their process safety due diligence responsibilities seriously.

Ready to take your process safety strategy to the next level?

Explore our PROCESS SAFETY TRAINING COURSES HERE, to build practical, defensible safety solutions. Contact us to enrol in Demonstrating SFAIRP Training Course to gain better understanding how to demonstrate risks are reduced.

Have questions or need guidance? Get in touch with our process safety consultants to discuss your facility risks and training needs.